Agricultural Literacy Curriculum Matrix

Lesson Plan

From Cow to Carton: Milk's Journey to the Consumer

Grade Level

Purpose

Students will explore milk production in the United States and explain the benefits of homogenization, pasteurization, and fortification of milk. Grades 6-8

Estimated Time

Materials Needed

Engage:

- Zoomed in on Dairy photo and key

- Cow to Carton timeline cards

Activity 1:

- Cow to Carton timeline cards

- Follow Milk’s Journey from Farm to Store video clip

Activity 2:

- Decoding Dairy video clip

Vocabulary

antibiotic: a medicine that inhibits the growth of or destroys microorganisms

fortification: the process of adding micronutrients (essential trace elements and vitamins) to food

homogenization: the process of reducing the size of fat globules in milk to extremely small particles so the cream does not separate from the milk

pasteurization: a process in which milk (or other liquid) is quickly heated to kill any potential disease-causing bacteria

standardization: a process in which milk is separated from the cream and then rejoined with different fat percentage levels (whole milk, 2%, 1%, or skim)

tanker: a road vehicle for carrying liquids, especially in bulk

Did You Know?

- Milk provides nine essential nutrients in each serving: protein, calcium, phosphorus, vitamins A and D and four B vitamins—B12, riboflavin, pantothenic acid and niacin.1

- On average, it takes two days for milk to travel from the farm to local stores.

- Milk has been fortified with Vitamins A&D since the 1930s and 40s.3

Background Agricultural Connections

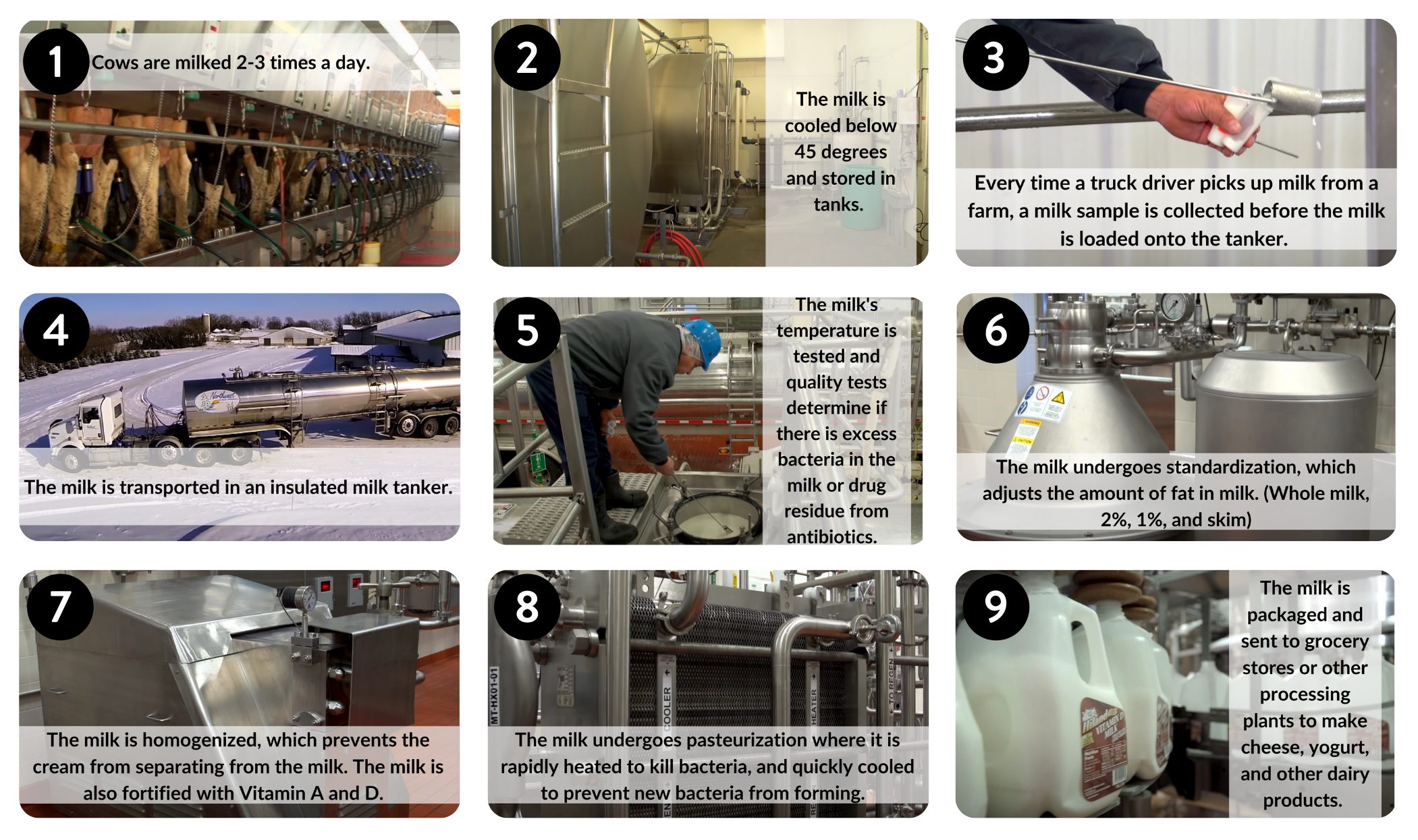

Milk comes from a cow and is produced on a dairy farm, but how does milk get to the grocery store? Milk’s journey starts with the cow. Dairy farmers ensure their cows are healthy and comfortable. This includes a nutritious diet, clean water, comfortable bedding, and an environment that’s not too hot or too cold. Occasionally, cows get sick and some dairy farmers will treat illnesses with antibiotics. If a dairy cow is currently milking and receiving antibiotics, her milk is not collected with the rest of the milk. Dairy cows are milked 2-3 times a day using mechanical and robotic milkers. These technologies are more comfortable for the cows and more efficient than milking cows by hand.

When cows are milked, the milk is the same temperature as the cow’s body—100 degrees. Using pipes hooked to the mechanical milkers, the milk immediately travels to a storage tank on the dairy farm where it is quickly cooled to below 45 degrees. Depending on the size of the dairy, insulated milk trucks (tankers) will visit the farm daily, multiple times a day, or every other day to pick up the milk. The driver of the milk tanker will collect milk samples from each tank on each dairy. Typically, a milk tanker will pick up milk from various dairies and haul all of the milk in one load. The milk is then delivered to a dairy processing plant where it will be tested for quality and safety.

At the milk processing plant, the milk’s temperature is taken again, and the milk in the tanker is specifically tested for any traces of drug residue from the use of antibiotics. If any drug residue is detected in the milk tanker, each milk sample that the truck driver collected at each dairy is tested. All of the milk from the tanker is discarded. Milk that is safe and free from drug residue continues through the processing plant and undergoes various processes including standardization, pasteurization, homogenization, and fortification. All of these quality tests and processes make milk one of the most regulated and safest foods you can buy at the store.2

Engage

- Project the Zoomed in on Dairy photo on the board.

- On a scratch piece of paper, ask students to identify each zoomed in photo.

- Allow students to share their guesses and write them on the board.

- Reveal the correct answers to students.

- Now ask students, “What do all of these products have in common?”

- Students should determine that each product is a dairy product and contains milk.

- Divide the students into pairs.

- Ask students to consider milk’s journey from cow to carton.

- How is milk processed? Why is milk processed before consumption?

- What happens to milk and dairy products before they are sold at the grocery store?

Explore and Explain

Activity 1: From Cow to Carton

- Pass out a set of Cow to Carton timeline cards to each pair of students.

- If necessary, ask students to cut out each of the cards.

- Instruct students to place each card in sequential order in which they think milk is processed from cow to carton.

- Show students the Follow Milk’s Journey from Farm to Store video clip.

- As students watch the video clip, allow them to rearrange their cards into the correct order, if needed.

- Ask students to think about milk’s journey. Consider asking the following questions to lead a class discussion:

- What surprises you most about milk production and processing?

- Why is cow’s milk one of the safest food sources at the grocery store?

- Why does milk undergo standardization?

- What is the purpose of homogenizing milk?

- Why is milk pasteurized?

Activity 2: Decoding Dairy: Understanding the Milk Label

- Project the Milk Carton Food Label photo on the board.

- Ask students to identify words or terms they recognize from Activity 1. (pasteurization, homogenization, Vitamins A & D)

- As the class identifies familiar terms on the milk label, have students identify the same terminology on their timelines. (e.g. as you point to pasteurization on the label, have students find the photo on their timeline that shows pasteurization taking place.)

- Show students the Decoding Dairy video clip.

- Review milk processing with students by going through each of the steps on the timeline and discussing concepts from the video clip.

Evaluate

Concept Elaboration and Evaluation:

After conducting these activities, review the concepts using individual whiteboards and dry erase markers. Student whiteboards can be made by putting white paper inside page protectors.

- Pass out a whiteboard and dry erase marker to each student and review the cow to carton process.

- Ask various questions and give students the appropriate amount of time to write their answers.

- Once students have finished writing, ask students to hold up their whiteboards for easy formative assessment.

- Consider asking the following review questions:

- What are the benefits of pasteurizing milk?

- Why is milk homogenized?

- Why does the truck driver collect milk samples at each dairy?

- What process prevents the cream from rising to the top?

- How do you know there aren’t any antibiotics in the milk you drink?

- What is the difference between BST and rBST?

- Why is milk fortified with Vitamins A&D?

- Are humans affected by hormones in cows’ milk?

- What is the process called when milk’s fat particles are broken down and evenly distributed?

- What process destroys harmful bacteria in milk?

Recommended Companion Resources

Author

Organization

| We welcome your feedback! If you have a question about this lesson or would like to report a broken link, please send us an email. If you have used this lesson and are willing to share your experience, we will provide you with a coupon code for 10% off your next purchase at AgClassroomStore. |